Glossary of Electrostatics

Surface tension is the force that causes fluids to pull together into spherical forms and resist the tendency to spread out

Atomization is the process of breaking liquids into droplets. Common home atomizers include shower heads, perfume sprayers, garden hoses, hair sprayers, etc. A classic example of atomization occurring naturally involves pouring liquid from a pitcher. As you are pouring and gradually lift the pitcher higher, the stream of liquid elongates and breaks into droplets at some point. This breakup of a liquid stream is a simplistic example of atomization.

A Spray is a collection of a variety of sizes of fluid droplets moving in a controlled fashion usually as a result of atomization. Naturally occurring sprays are rain and ocean sprays.

Droplets are small particles of liquid having a more or less spherical shape. Droplets are also known as particles. The reason particles are round is due to the liquid’s surface tension.

Surface tension tends to stabilize a fluid, preventing its breakup into smaller droplets. Everything else being equal, fluids with higher surface tensions tend to have a larger average droplet size upon atomization.

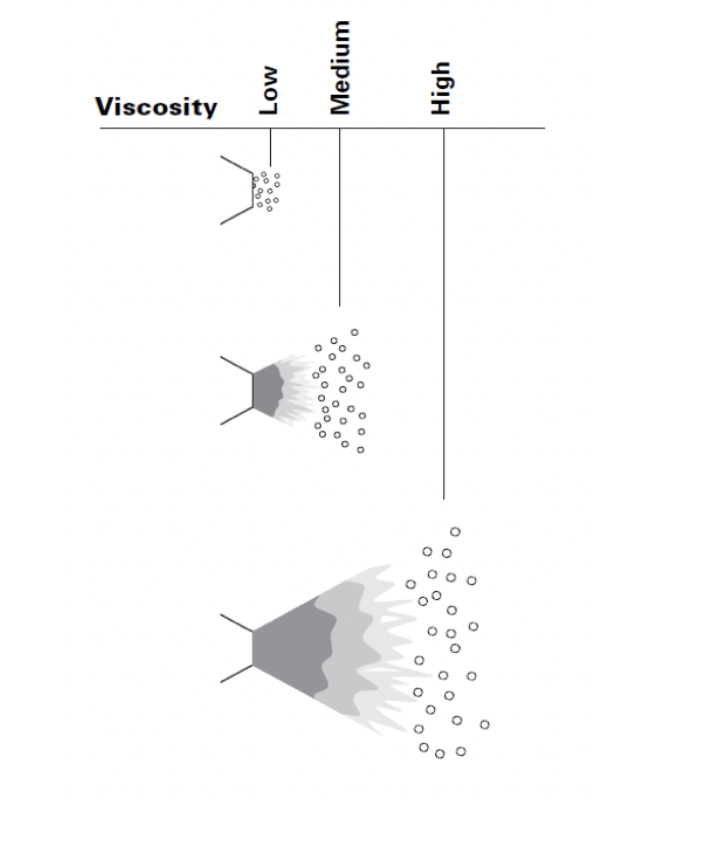

Viscosity - A fluid’s viscosity has a similar effect on droplet size as surface tension. Viscosity causes the fluid to resist agitation, tending to prevent its breakup and leading to a larger average droplet size.

Density causes fluid to resist acceleration. Similar to the properties of both surface tension and viscosity, higher density tends to result in a larger average droplet size.

Atomization Processes Pressure (Airless) Atomization

Other terms for pressure atomization include airless, air-assisted airless, hydrostatic and hydraulic technology.

In the airless atomization process, high pressure forces fluid through a small nozzle. The fluid emerges as a solid stream or sheet at a high speed. The friction between the fluid and the air disrupts the stream, breaking it into fragments initially and ultimately into droplets.

The energy source for this form of atomization is fluid pressure, which is converted to momentum as the fluid leaves the nozzle.

Three factors that affect an airless spray include the atomizer orifice diameter, the atmosphere, and the relative velocity between the fluid and the air. Regarding orifice diameter, the general rule is that the larger the diameter or size of the atomizer orifice, the larger the average droplet size in a spray.

The atmosphere provides resistance and tends to break up the stream of fluid. This resistance tends to overcome, in part, the fluid’s properties of surface tension, viscosity, and density. In addition, the air temperature may also affect atomization.

The relative velocity between the fluid and the air also affects droplet sizes. The fluid’s velocity is created by pressure in the nozzle. As the fluid pressure increases, velocity increases and the average droplet size decreases. And conversely, as fluid pressure decreases, velocity is lower and the average droplet size is larger.

Figure 5 illustrates a simple circular orifice injecting a round stream of fluid into the atmosphere. The fluid is under pressure and is breaking up into a spray.

In air-spray atomization, fluid emerging from a nozzle at low speed is surrounded by a high-speed stream of air. Friction between the liquid and air accelerates and disrupts the fluid stream and causes atomization, the creation of droplets.